Potato Chips Production Line

High-speed automation ensures crispy, uniformly sliced chips with customizable flavors to meet global market demands.

online message

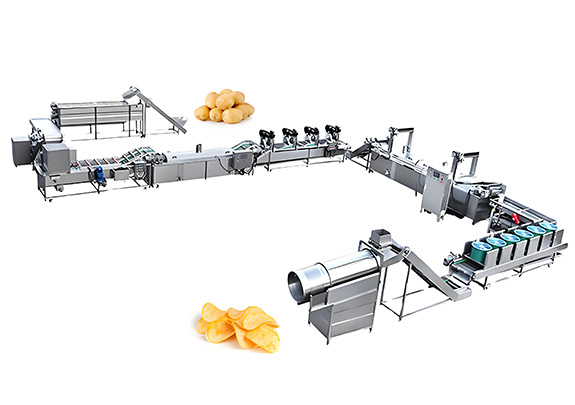

This fully automated potato chips production line integrates multiple processes including elevating/conveying, washing/peeling, manual sorting, cutting, bubble washing, vibration dewatering, air drying, frying, oil removal, cooling, quick-freezing, and packaging. With customizable output ranging from 50-5000KG/H, the entire line is constructed with food-grade SUS304 stainless steel and features PLC touchscreen control.

High-speed automation ensures crispy, uniformly sliced chips with customizable flavors to meet global market demands.

Advanced blanching and freezing technology preserves natural taste and texture, delivering restaurant-quality fries at scale.

IQF (Individual Quick Freezing) system maintains freshness and minimizes clumping, ideal for long-term storage and export.

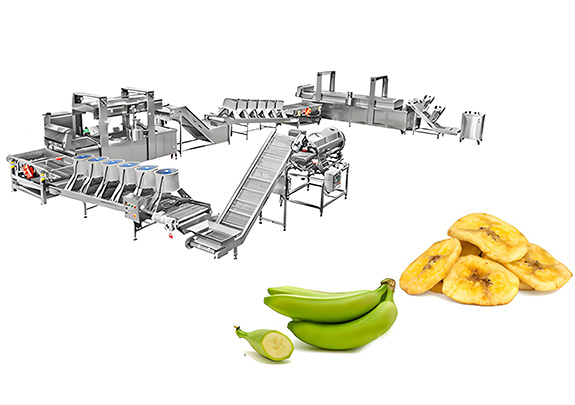

Low-oil frying innovation produces healthier, crunchy banana chips with retained nutritional value and tropical flavor.

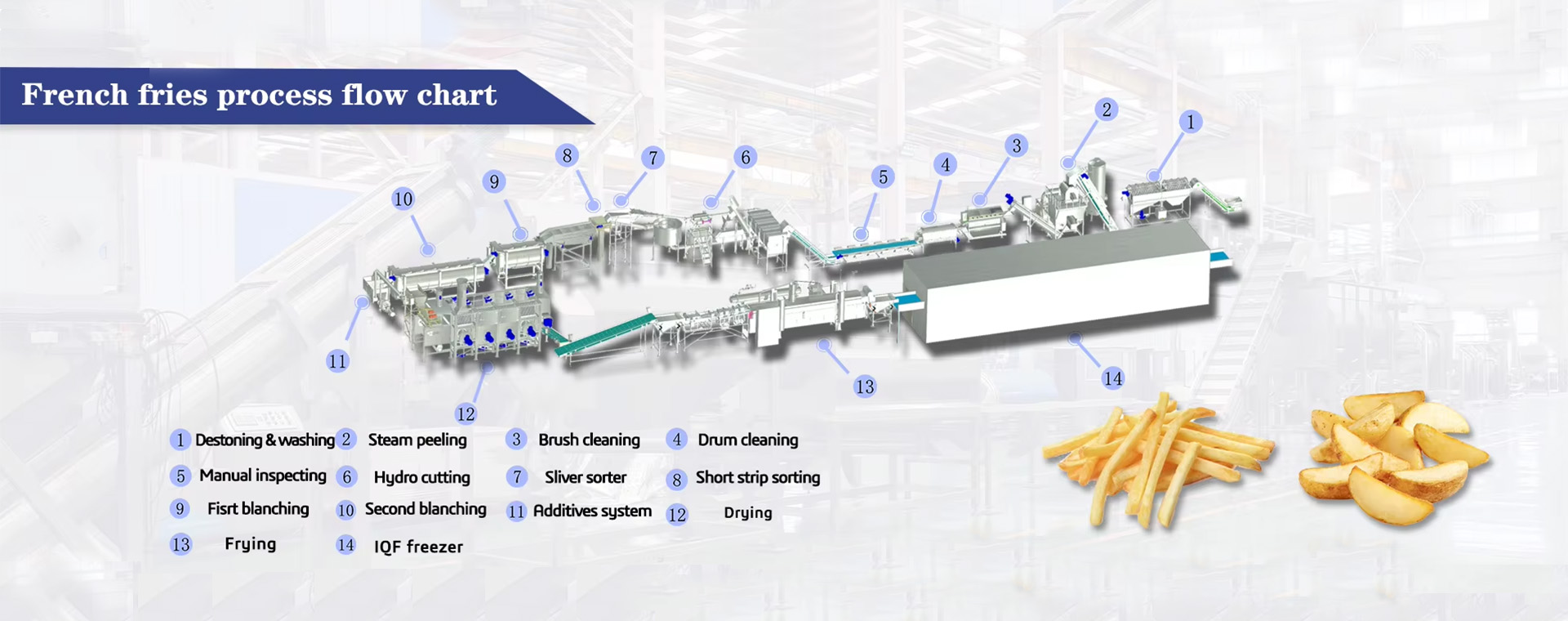

Processing Flow: Pre-Washing→Grading→Lifting And Loading Machine→Brush Cleaning And Peeling Machine→Picking Line→Strip Cutting Machine→Lifting Machine→Corner Removal Machine→Long And Short Strip Screening Machine→Rinsing Machine→Blanching Machine→Air-Cooled Draining Machine→Lifting Machine→Drying Machine→Lifting Machine→Frying Line→Vibration Oil Draining Machine→Quick Freezing Machine→Packaging Machine

Elevate & De-stone: Raw potatoes elevated to roller washer for stone removal and grading.

Clean & Peel: Remove soil and skin fragments for cleanliness.

Manual Sort: Inspect on conveyor; remove eyes/spoilage; cut large potatoes.

Cut Strips: Process peeled potatoes into fries.

Starch Rinse: Rinse cut strips to remove surface starch.

Trim Defects: Remove broken pieces and irregular edges.

Blanch: Treat in 50-60°C water to gelatinize starch and control enzymes.

Air Dry: Remove surface moisture with blowers.

Fry: Continuously fry at 170-185°C for 2.5 minutes.

De-oil & Level: Vibrate to remove excess oil and spread evenly.

Quick Freeze: Rapid-freeze to lock cellular structure.

Package: Vacuum/N₂-seal to preserve crispness and shelf life.

1. Precision Processing with Cutting-Edge Technology

Optical/X-ray sorting ensures only high-quality potatoes are used, minimizing waste.

High-pressure water jet cutting reduces starch leakage, enhancing crispiness while eliminating blade wear.

2. Energy Efficiency & Sustainability

Heat recovery systems recycle thermal energy from fryers for preheating oil/water.

Closed-loop water reuse in blanching and cleaning processes conserves resources.

3. Consistent Quality via Automation

AI-powered vision systems monitor color, size, and defects in real-time.

Multi-zone frying control guarantees uniform texture and golden hue across batches.

4. Extended Shelf Life & Food Safety

Individual Quick Freezing (IQF) preserves cellular structure for optimal reheating results.

Nitrogen flushing packaging prevents oxidation, maintaining freshness for months.

Precision coating technology ensures consistent, high-adhesion breading with minimal waste for uniform, restaurant-quality chicken, fish, and plant-based products.

Gentle washing, cutting, and preservation systems maximize yield, shelf life, and nutrient retention while maintaining fresh sensory qualities for both fresh-cut and frozen segments.

Foodline Machinery is a professional food machinery manufacturer and exporter with over 20 years of industry experience. We specialize in providing comprehensive solutions including design, installation, commissioning, and training for various food production lines. With three production workshops, more than 30 CNC processing equipment, and 40 skilled technicians, we ensure the precision and performance of our products. Our engineers possess extensive expertise with 20+ years of experience in food machinery manufacturing, capable of delivering complete solutions covering all project phases from basic/detailed design to manufacturing, pre-assembly, transportation, installation, commissioning, and startup.