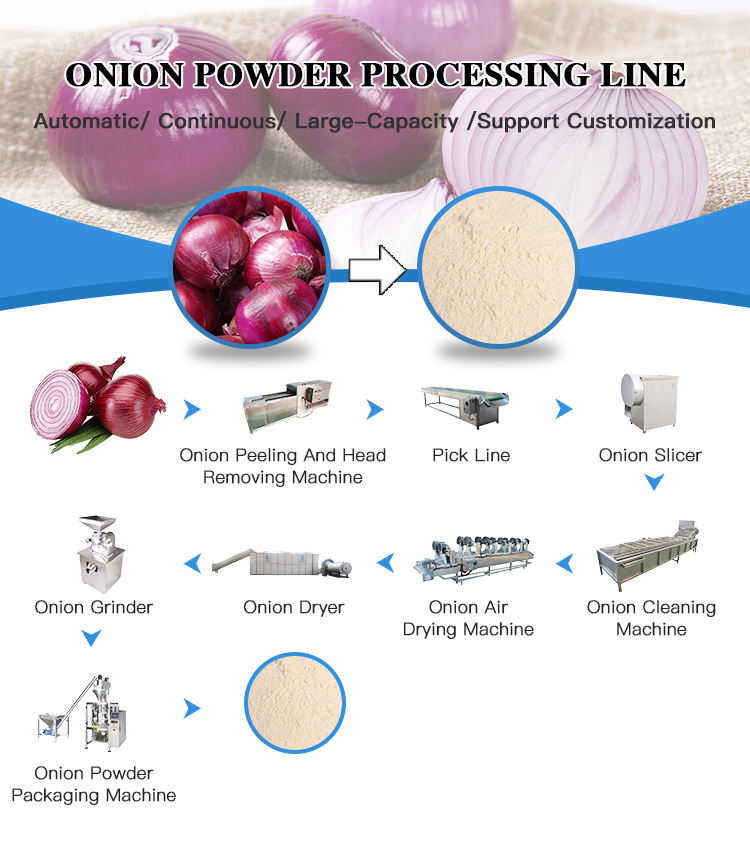

Automation: Reduces manual labor and handling, minimizing bruising and spoilage.

High Efficiency: Capable of processing large volumes of onions, with high peeling rates.

Gentle Processing: Uses air pressure or other methods to remove skins without cutting the onion, preserving product quality.

Versatility: Can handle various onion sizes, shapes, and conditions (wet or dry) without requiring specific grading.

Dry Peeling: Eliminates water usage and the need to handle wet waste, simplifying disposal and keeping the product dry.

Cleanliness and Hygiene: Produces smooth, fresh, peeled onions without contamination, meeting sanitation standards.

Optional Root/Tail Cutting: Many lines integrate this function for a complete, automated onion preparation process.