online message

The continuous fryer is an automated industrial food processing machine designed for high-volume production. It features precise temperature control, uniform frying, oil filtration, and continuous conveyor operation, ensuring consistent product quality with high efficiency. Ideal for snacks, frozen foods, and fried products.

Processing Flow: Pre-Washing→Grading→Lifting And Loading Machine→Brush Cleaning And Peeling Machine→Picking Line→Strip Cutting Machine→Lifting Machine→Corner Removal Machine→Long And Short Strip Screening Machine→Rinsing Machine→Blanching Machine→Air-Cooled Draining Machine→Lifting Machine→Drying Machine→Lifting Machine→Frying Line→Vibration Oil Draining Machine→Quick Freezing Machine→Packaging Machine

Elevate & De-stone: Raw potatoes elevated to roller washer for stone removal and grading.

Clean & Peel: Remove soil and skin fragments for cleanliness.

Manual Sort: Inspect on conveyor; remove eyes/spoilage; cut large potatoes.

Cut Strips: Process peeled potatoes into fries.

Starch Rinse: Rinse cut strips to remove surface starch.

Trim Defects: Remove broken pieces and irregular edges.

Blanch: Treat in 50-60°C water to gelatinize starch and control enzymes.

Air Dry: Remove surface moisture with blowers.

Fry: Continuously fry at 170-185°C for 2.5 minutes.

De-oil & Level: Vibrate to remove excess oil and spread evenly.

Quick Freeze: Rapid-freeze to lock cellular structure.

Package: Vacuum/N₂-seal to preserve crispness and shelf life.

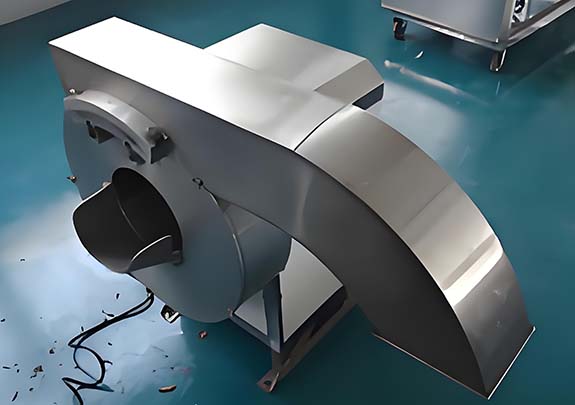

Equipped with an oil storage tank and exhaust hood, this fryer handles French fries with adjustable temperature (0-220°C), variable-frequency speed control for frying time, and a feed inlet upgraded with a material-pushing device.

A continuous fryer efficiently cooks various foods like fries, chips, chicken, fish, onion rings, spring rolls, doughnuts, and breaded/battered items. Suitable for both fresh and frozen ingredients, it ensures consistent quality in large-scale production.

Automated system precisely controls oil temp, frying time, and conveyor speed for even heating, ensuring consistent product quality in color, texture, and oil absorption.

Continuous conveyor belts eliminate downtime, integrating with pre-processing/packaging for high output (fries/chips/nuggets) and lower labor costs via full automation.

Stainless steel construction resists corrosion and simplifies cleaning. Customizable for varied needs, with oil filtration to prolong oil life.

Heat recovery tech reduces energy waste. Versatile for snacks, frozen items, and nuts, saving space vs. batch systems.

Foodline Machinery is a specialized Chinese manufacturer of food processing equipment, offering industrial fryer, continuous fryer, conveyor fryer, vacuum fryer, and Various food processing production lines. With decades of experience and a skilled technical team, we provide integrated R&D, production, and service solutions. Our products are exported worldwide, serving markets across Europe, the Americas, Africa, and Southeast Asia.