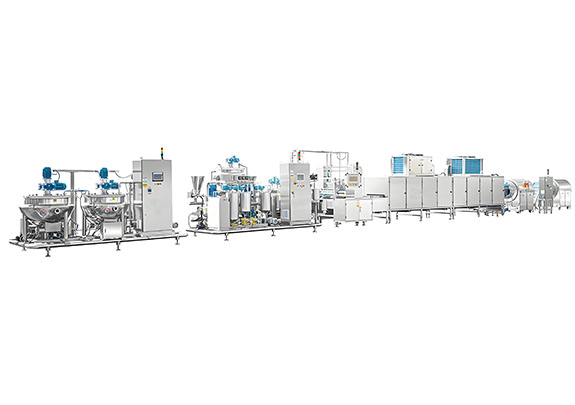

Cooking System

The stainless steel cooking system features a jacketed cooker and storage tank on a rack, controlled by an electric cabinet. Raw materials (glucose syrup, sugar, water, etc.) are dissolved and boiled in the cooker (electric or steam heated), then pumped to the warm-water-jacketed storage tank for temperature maintenance and uniformity. Finally, the syrup is pumped to the depositing machine for continuous production. The entire setup facilitates easy operation and cleaning.

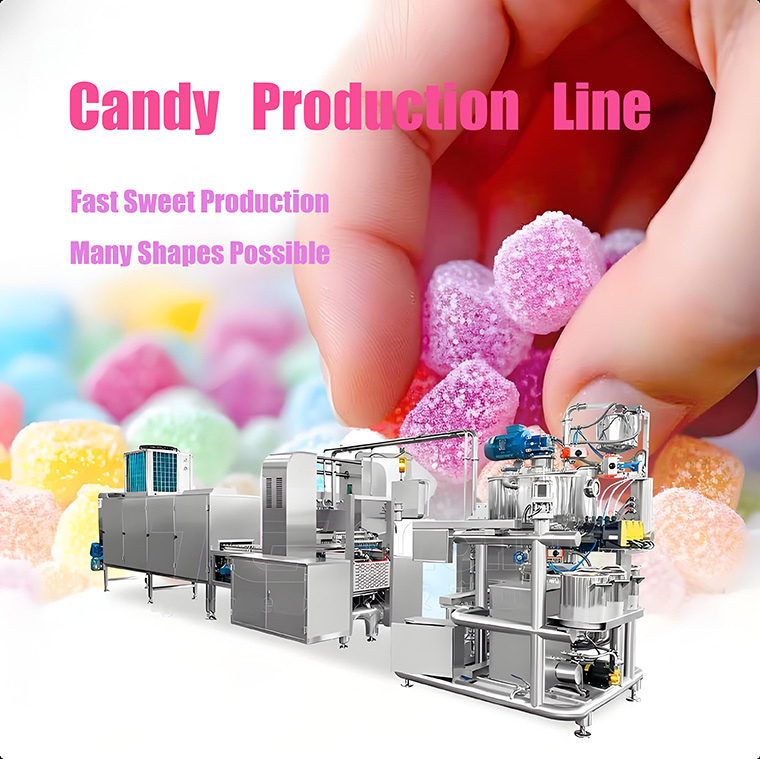

Depositing & Cooling Unit

The advanced depositing machine utilizes cutting-edge production technology to enable continuous, automated manufacturing of high-grade candies, including single-color, double-color, and center-filled varieties. Recent R&D improvements have optimized performance, enhanced automation, and extended equipment lifespan.

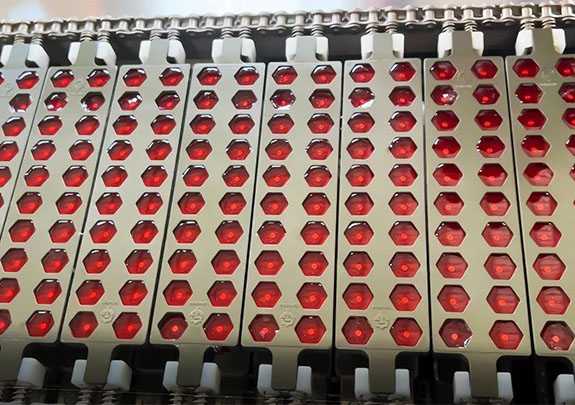

Mold with Quick Release Tool

The molds, featuring Teflon-coated metal or silicone rubber construction with mechanical/air ejection, are arranged in easily removable sections for quick product changeovers and cleaning. They produce gummy shapes (e.g., bear, bullet, cube) with weights ranging from 1g to 15g.